May 12, 2025 · Innovators

From Mobile to the Control Room: Ai-OPs Scales Industrial AI

In Alabama’s port city, a small startup is quietly leading a big shift in industrial automation.

Ai-OPs, founded in Mobile by longtime engineers Phillip Hansel, Curtis Wright, Ryan Hutchison and Connor Smith isn’t chasing the next viral app or virtual assistant — it’s focused on engineering applications that enable industrial AI to drive performance in real-world environments, not novelty on a screen. Their focus is mission critical: embedding AI into the factory floor in a way that not only delivers tangible results, but also endures the lifecycle, rigor and expectations of the industries they serve.

The Ai-OPs solution consists of two core products:

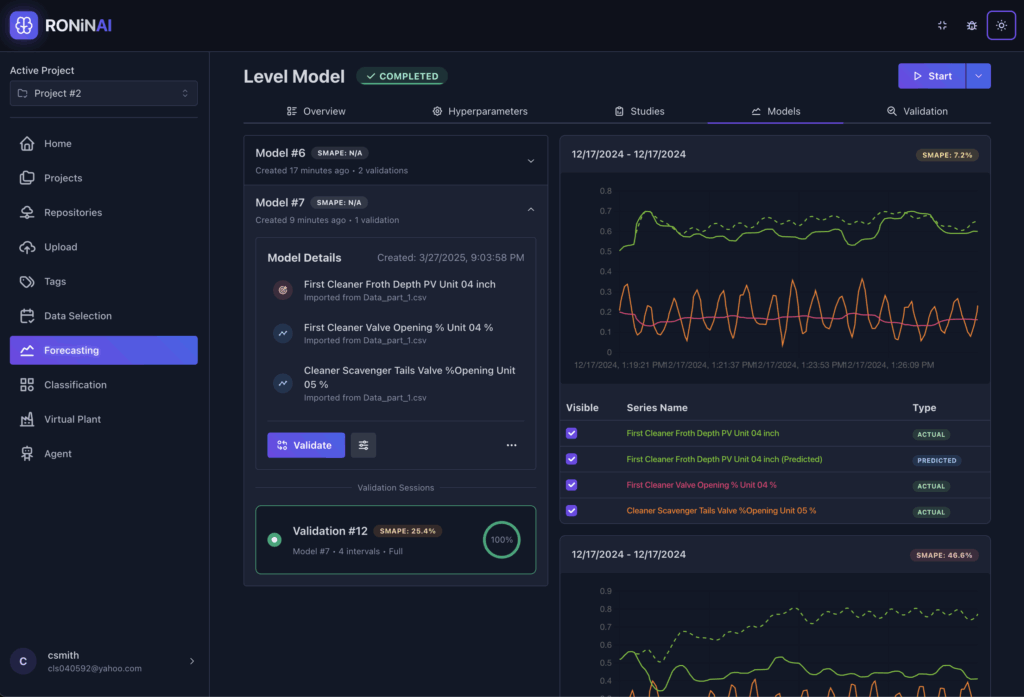

Ronin – An enterprise-grade application where engineers and data scientists build, train and sustain machine learning (ML) models tailored for industrial processes. Ronin enables organizations to own their models — from design through deployment — without needing a PhD in data science. Full production by 2026.

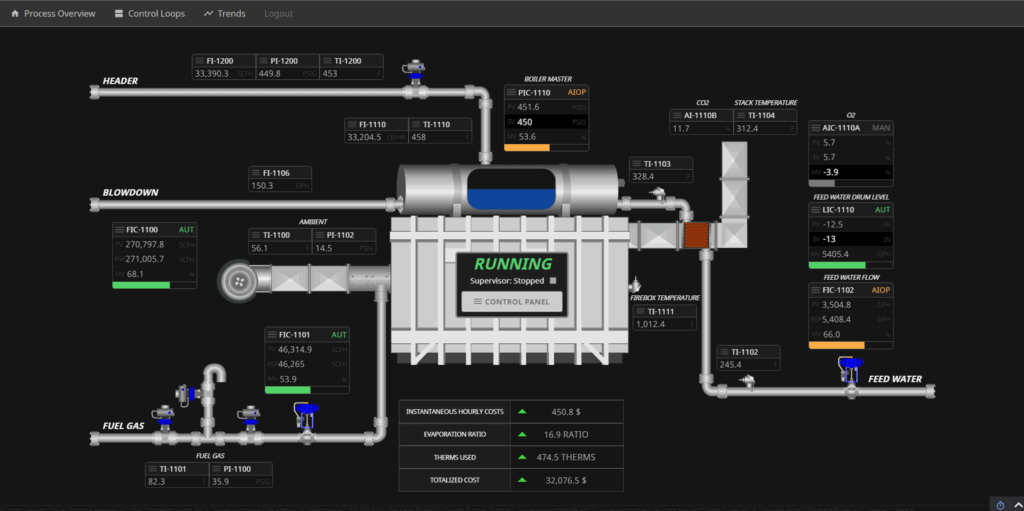

Koios – A self-hosted inferencing platform that deploys those trained models directly into production systems. Koios runs alongside control systems (DCS, PLC, SCADA) using standard industrial protocols and supports air-gapped, real-time and hardware-agnostic deployments.

This combination enables Ai-OPs to deliver what traditional optimization software hasn’t: high-speed, highly reliable, closed-loop control using Deep Reinforcement Learning (DRL) and other ML techniques, directly interfacing with production hardware to stabilize systems, reduce cycling and improve yields.

The cofounders saw the gap firsthand. After years in industrial control systems, they kept running into the same issue: plants were generating massive amounts of data, but there was no simple way to use it. Engineers were stretched thin. Upgrades were expensive. The tools to improve efficiency existed — the scalable path to deploy them did not.

That’s where Ai-OPs comes in.

The startup took root at Mobile’s Innovation Portal, an incubator for early-stage ventures supported by the Innovate Alabama Tax Credit Program. But the team didn’t stop there. In late 2023, they became the only Mobile-based startup accepted into the Techstars Alabama EnergyTech Accelerator in Birmingham. The program gave them critical exposure to investors, industry leaders and other founders tackling energy challenges from multiple angles.

Soon after, they joined gBETA Gulf Coast, a gener8tor-backed pre-accelerator that helped them sharpen their strategy and prepare for growth. Within months, that groundwork paid off.

In early 2024, Ai-OPs announced a $1.3 million strategic investment from TriNova Inc. – a leader in industrial product solutions, instrumentation services and technical training – headquartered in Mobile, AL. With funding and a go-to-market partnership secured, the team shifted into full-time operations and began deploying Koios in the field.

At one of the company’s first industrial installations, Koios delivered measurable results. The system helped stabilize temperature fluctuations, reduce valve cycling and extend run times between maintenance intervals. After seeing the improvement, the operations team had one question: When can we use this in other units?

That kind of response gave Ai-OPs the confidence to move quickly. Since then, the company has begun expanding its reach internationally, building partnerships and exploring opportunities in oil and gas across the Middle East, manufacturing in Europe, mining and minerals in Canada, utilities in the United States and even commercial building optimization around the globe.

Ai-OPs made the most of the tools around them. Programs like gBETA and Techstars gave them the right support at the right time. The Innovate Alabama Tax Credit Program helped bring capital to the table. Each step pushed the company forward.

“We don’t think small — we think big, and we move fast,” said Hansel. “We’re not just building tools for today’s problems; we’re designing the engineering foundation that industrial AI professionals will rely on for the next 20+ years. This isn’t about hype — it’s about reshaping how facilities operate, how engineers build and how decisions get made at scale. Our mission is to make industrial AI not only powerful, but practical and enduring.”

Today, Ai-OPs is focused on continuing to focus on scale. The team is expanding. New installations are in motion. They’re working with system integrators to bring Koios and Ronin into new sectors, from manufacturing to utilities. And while the company’s footprint is expanding, their foundation remains local.

Kelly McNair, program director for the Innovate Alabama Tax Credit Program sees Ai-OPs as a sign of how the state’s innovation pipeline is evolving. “What stands out isn’t just the technology. It’s how grounded their approach is,” she said. “They understand their industry, they’re building something that solves a real need and they’re doing it here in Alabama. That’s exactly the kind of work we’re proud to support.”

Ai-OPs is still early in their journey, but the impact is already taking shape. You can see it on shop floors, in control rooms and in the way Alabama is rethinking what innovation looks like.

Progress doesn’t always come from overhauling what’s broken. Sometimes it comes from understanding what works and making it smarter, more resilient and easier to trust.

Ai-OPs understands that. And they’re just getting started.

Get the Download

The latest stories of inspiration and innovation happening all around our state, right to your inbox.