September 16, 2024 · Innovators

Making Cancer Drug Screening Easier and Faster: A Spotlight on Grant Recipient Vivosphere

Testing the efficacy of cancer drugs is a daunting task for researchers.

During the cancer drug discovery process, researchers need to screen many drug compounds to gain insights into drug efficacy and safety and eliminate non-effective or toxic compounds.

Making that happen at the volumes required is easier said than done.

Auburn-based VivoSphere™, founded by Elizabeth Lipke and Yuan Tian, is pioneering cell response testing technology with the help of an Innovate Alabama SBIR/STTR Supplemental Grant.

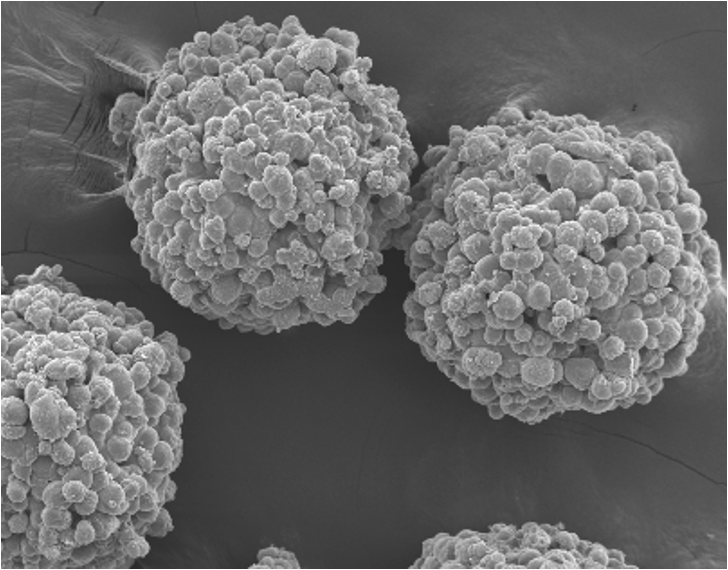

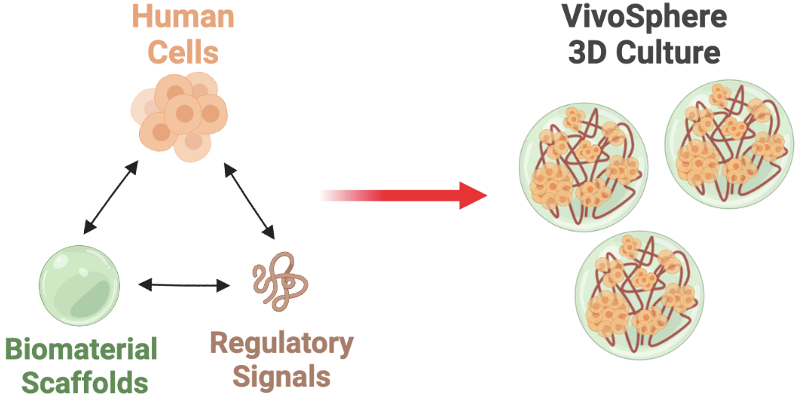

VivoSphere provides 3D cell culture models for in vitro drug discovery and toxicity testing using tissue engineering technologies. VivoSpheres are spheroidal engineered hydrogel microtissues made using a patented microfluidic cell encapsulation platform to achieve high production rate and consistency.

The technology was developed by Dr. Elizabeth Lipke’s research group at Auburn University. It aims to strike a balance between throughput, which includes high-volume scalability and uniformity, and the ability to modulate key attributes of the cancer tumor microenvironment.

VivoSpheres are proving to be superior to current two-dimensional (2D) cell culture-based and three-dimensional (3D) cell aggregate-driven drug screening approaches. Those approaches do not provide cells with the necessary microenvironmental cues to emulate human patient drug response, leading to costly failures during in vivo preclinical studies or clinical studies.

The Innovate Alabama SBIR/STTR Supplemental Grant will help VivoSphere address a major hurdle – shipping.

Under typical culture conditions, VivoSpheres in the cell culture medium settle. However, during shipment, the package may be tossed, resulting in media leakage and tissue damage. The project’s overarching goal is to develop a shipping method for assay-ready VivoSpheres that reduces the impact of extreme shipping conditions, such as package tossing, temperature fluctuations and delivery delays.

Another challenge is preserving the structure and functionality of the complex microtissues during multi- day shipping. Culturing microtissues typically requires high humidity, high CO2 levels and robust thermal management. In a lab setting, this is achieved through sophisticated cell-culture incubators. Providing a similar environment in a transport system is possible, as such highly specialized shipping systems exist, but they are typically heavy, expensive and often cannot be transported by regular express parcel services. VivoSphere intends to develop a packaging system to control the shipping environment, reducing the loss of viability and functionality.

The grant’s objectives include:

- Designing a well-plate sealing mechanism to prevent medium leakage.

- Testing different packaging approaches to maintain the samples at room temperature.

- Performing shipping tests and evaluate packaging integrity and tissue viability post shipping.

VivoSphere also aspires to use the project grant to stimulate economic growth in the state. The company plans to reach out to investors and apply for additional Phase II SBIR funding to foster business growth, build management teams and establish manufacturing capabilities. The company’s research will help the state in creating exportable products and services, creating and retaining high-wage jobs in both moderately and highly skilled occupations, and stimulating the biotech startup ecosystem.

Get the Download

The latest stories of inspiration and innovation happening all around our state, right to your inbox.